Benedetto Cavalieri

First Choice Pasta with Name and Surname

Benedetto Cavalieri: the beginning of a good pasta tradition

The history of the Benedetto Cavalieri pasta factory begins many years ago.

The Cavalieri Family has been committed to the growing of durum wheat in purposely chosen fields in the heart of Apulia since the 19th century.

The agricultural crisis following the unification of Italy (1861) pushed the Cavalieri family towards new activities. In 1872 Andrea Cavalieri started foreign trading of durum wheat and, later, constructing millstones planned for the best milling of the durum wheat.

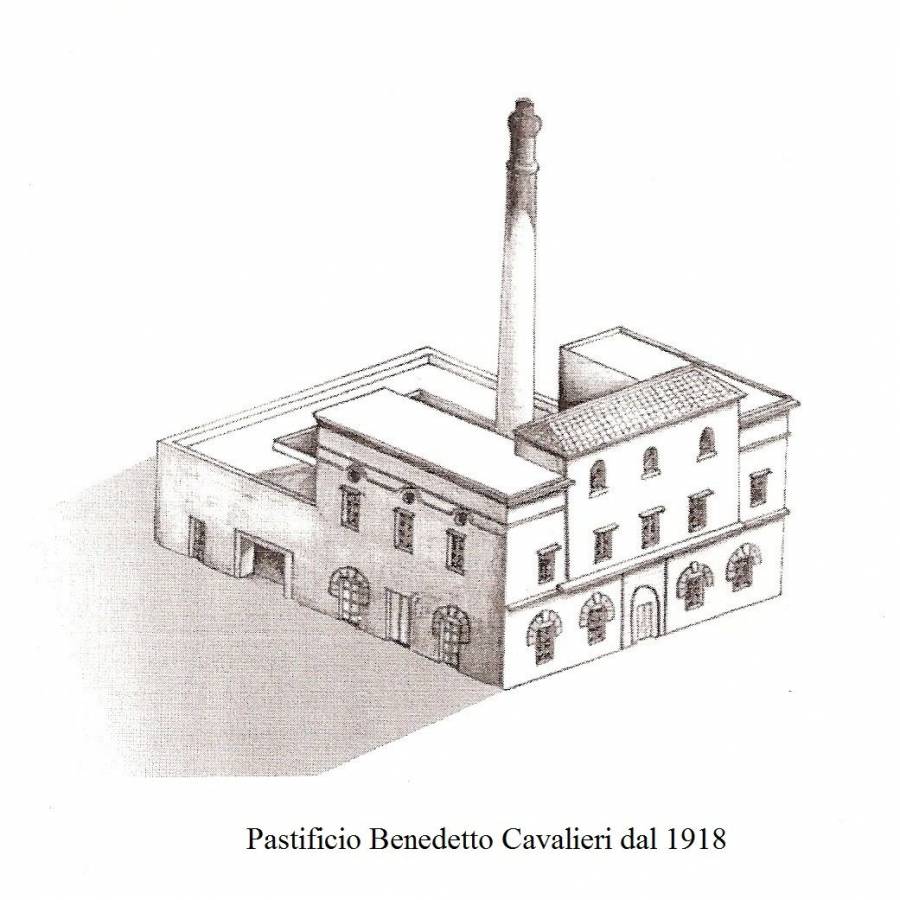

With the heritage of his father’s experiences in the durum wheat cultivation and milling, on July the 7th 1918 Benedetto Cavalieri inaugurated in Maglie the Mill and Pasta Factory Benedetto Cavalieri. The idea was clear: to produce First Choice Pasta with his ‘fine and selected’ durum wheat from the sunny hills of Apulia. From that day on the motto has been:

«Every package of pasta will gain credit from the previous one».

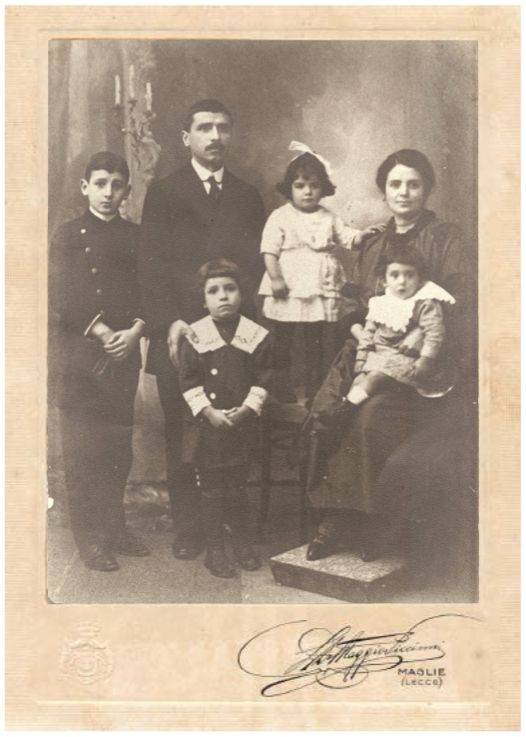

Benedetto Cavalieri and his family on the day of the inauguration of the Mill and Pasta Factory

SHOP ONLINE PASTA BENEDETTO CAVALIERI AND THE BEST ARTISAN AUTHENTIC ITALIAN FOODS

On Gustorotondo you find Benedetto Cavalieri pasta and good Italian foods.

We look for producers who have high-quality standards, and we offer artisan Italian good products that enhance the tradition and authentic flavours of Italian cuisine.

Gustorotondo was born as a traditional Italian food store in the center of Milan, and then started the e-commerce business. Now you can buy traditional Italian food online on Gustorotondo from all over Italy, from England, from Germany, from Holland and the Netherlands, from the Czech Republic, and from all the other European countries.

Shop online the best authentic artisan Italian food at Gustorotondo!

Benedetto Cavalieri pasta: innovation and quality

Since the founding Benedetto Cavalieri aims at innovation and quality using up to date machinery for kneading, pressing and drawing. To prevent the drying of pasta in the streets, a customary practice at the time, he introduced a new system called ‘Metodo Cirillo’.

The ‘Cirillo Method’, whose name comes from the name of his inventor, Michele Cirillo, an engineer from Torre Annunziata, near Naples, simulates the natural drying method inside a pasta factory, combining a hot water heater and a fan under the supervision of the Capo-pastaio.

Benedetto Cavalieri pasta: the new generations

During the ’50s, Benedetto hands on the baton to his son Andrea who gives the Firm a managerial structuring and transmits the family keenness for pasta to his son Benedetto, the present owner.

Benedetto has been running the firm for more than 30 years, winning and reaching a great number of national and international awards and consolidating the presence on foreign markets.

Andrea, representing the fourth generation of pasta makers, entered the Firm in 2007 and together with his father he is bringing on the family tradition with great enthusiasm and seriousness.

Benedetto Cavalieri Pastas have won 2 SOFI (Specialty Outstanding Food Innovation) Awards from the National Association for the Specialty Food Trade, NASFT (now SFA, Specialty Food Association)

Carefully selected raw materials

Raw materials are rigorously selected. They grow in purposely chosen fields especially on the hills of Apulia and Basilicata (South of Italy); the durum wheat is cultivated without the usual massive use of chemical fertilizers that increases the quantities at the expense of quality.

The ‘Delicate Method’: mixing, kneading, pressing and drawing

The Founder developed a method, called ‘Delicate Method’: the long kneading, the slow pressing, drawing and drying at a low-temperature permit to preserve the nutritional values of the durum wheat, its taste and typical flavour and a completely natural consistency which is still so highly esteemed by gourmets.

Within the ‘Delicate Method’ can be identified four stages:

1. The mixing and kneading stage. In this part of the process, the durum wheat semolina passes from special silos to a measuring device that releases the correct amount of water and semolina. Cold kneading (not above 35°), controlled by experienced hands, prevents ‘thermic denaturation’ of gluten, the precious nutritional substance contained in the wheat.

2. The pressing and drawing stage. The dough is automatically pressed into a mould with gentle pressing to prevent the ‘mechanical destruction’ of gluten and carbohydrates. For each shape of pasta there is a different mould, produced by a special bronze alloy, with lots of holes. The dough passes gently through these holes to take its final form: spaghetti, penne, paccheri and so on.

A mould made of a special bronze alloy

Cavalieri Pasta and the ‘Delicate Method’: drying and stabilization stages

Production of Spaghettoni Benedetto Cavalieri

3. The drying stage.

This part of the process is particularly important to preserve the nutritional values of proteins and carbohydrates.

Unlike in the industrial high-temperature drying systems, in which the temperature reaches 120°C with a drying time up to 3 hours, the temperature of the air in the drying room is always equal or lower than 54°C and that pasta reaches only 40°C. Due to a difference in shape and thickness each cut of our pasta has a different drying period which varies from 24 to 40 hours.

Long cuts (e.g. spaghetti) right after drawing are hung on reeds and subjected to a drying process that takes place in drying rooms and alternates moderately warm ventilation with rest periods.

Short cuts (e. g. penne) are cut into segments by special motor knives while coming out of the mould and are placed on conveyor belts that push them into the drying room where they undergo the similar drying treatment described above for spaghetti pasta.

Thanks also to the low temperature, the Delicate Method preserves the precious biological and nutritive values of durum wheat (carbohydrates and vegetable proteins, basis of the Mediterranean Diet. At the same time, it brings out a unique taste and a completely natural consistency which are still much appreciated today.

4. The stabilization stage: once the drying process has taken place, the pasta rests for approximately 24 hours in an advisably air-conditioned room before being weighed and packaged.

Benedetto Cavalieri and the Slow Food University of Gastronomic Sciences

Since 2005, Pastificio Benedetto Cavalieri has been appointed Learning Centre of Slow Food University of Gastronomic Sciences of Pollenzo (Piemonte). The thematic one-week seminars on pasta-making are attended by students who come from the five continents.